Engine timing and installation of the timing belt

It is called synchronization engine operation to correctly match each cylinder pistons with high voltage supply in their respective plugs.

If not taken this synchronization is certain that the engine will not turn and if ignited explosions can occur in a sequence ending damaging some engine components, such as timing belt or gears.

Engine synchronization is required when changing time band, when a rocker either intake or exhaust is changed when the valve seals are changed, when the flute rocker is changed when a change of rings is pistons, when the valve head gasket is changed, when intake or exhaust valves and their springs are changed, when the valve seats are rectified.

BEFORE STARTING THIS PROCEDURE DISCONNECT NEGATIVE BATTERY TERMINAL FIRST.

The car should be raised with the cat mechanical front axle supported on towers or trestles car, freeing the tires.

To begin we must ensure that the cylinder piston No. 1 - the first on the left watching the engine with the hood open, is in the Top Dead Centre (TDC).

Means TDC of a cylinder when the piston is in the highest position, thus having the smallest volume and the largest compression cylinder.

To achieve this we in fifth gear, retired spark plug from cylinder No. 1 to confirm visually the piston reaches the highest point, and manually turn the front wheels to make the piston is up.

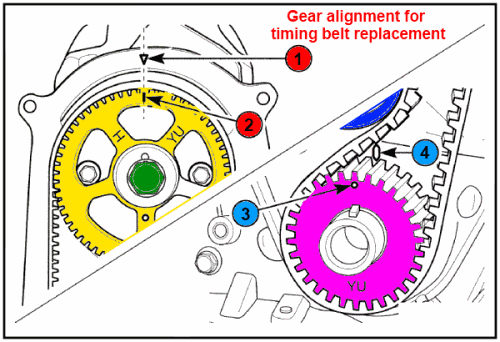

The mark 3 crankshaft sprocket must match the 4 mark on the engine block, as shown in the following graph:

Then it will be necessary to align the marks 1 and 2, for which we use a 17 mm socket wrench on the nut-camshaft found in green in the diagram above.

Turn the camshaft, with the 17mm socket wrench and ratchet several times to achieve the position described below.

The top-toothed pulley that is the camshaft pulley and is found in yellow, has two marks on edge of which corresponds to the TDC (Top Dead Center) and the other at Bottom Dead Center (BDC).

To confirm that the mark 1 and 2 are aligned at TDC, we introduce a thin rod through the spark plug hole No. 1 - which we removed earlier, and with this rod touch the piston or plunger, ensuring that up.

With these adjustments already made can put the timing belt without losing alignment achieved. Installed the timing belt, we must tighten, to thereby adjust the tension-that gear is in blue.

These settings can be sure that there will be no complications with timing and we can start the engine to test it.

Before testing engine, we must ensure that there is no bolt and / or nut loose or that we may have forgotten to install, do not fall also review tools and / or parts of the engine.