Chevrolet Silverado IAC Valve

The Chevrolet Silverado IAC valve manages air flow to the engine.

It works only to regulate the rpm at idle and engine ignition.

When starting the engine, the valve IAC Chevrolet Silverado delivers large amount of air in the intake manifold of the engine, so that the RPMs are at a high value and the engine is accelerated, but as the engine heats RPM stabilizes at its normal value.

Once the engine has reached its normal operating temperature, RPM should not vary if there is no external demand.

This external demand can be stomped on the accelerator or on electrical equipment of the truck that demand greater energy: as air conditioning, lighting, ventilation, etc.

For this reason, if the IAC valve operates properly should be noted a slight increase in engine RPM of the Silverado when we turn on the headlights. The same happens if we turn on the air conditioning, although it is possible that the noise does not allow air to hear the increase in RPM, but we can look at the tachometer: a slight increase in RPM will be noticed.

A failure in the IAC valve, either electrical or mechanical result in unstable RPMs, difficulty in starting the engine or completely prevent ignition if the IAC valve completely blocks access air.

The following describes other features of the IAC valve, where it is in the engine, and testing of the coils, lubrication to prevent binding, seal integrity, connector and terminals.

Operation of the Chevrolet Silverado IAC valve

The IAC valve is a stepper motor, IS NOT A DIRECT CURRENT MOTOR.

In short DO NOT OPERATE CAN DIRECTLY CONNECTING THE BATTERY.

IAC valve requires a pulse sequence to rotate.

For this situation Chevrolet Silverado computer (ECU / ECM or PCM) is responsible for generating and delivering the correct sequence of pulses to each coil stepper motor of the IAC.

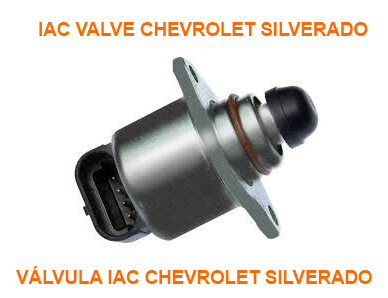

The tip of the shaft of the IAC valve is a stop-black color, as seen in the accompanying photograph, this cap regulates the flow of air into the combustion chambers of the engine idles, ie, this valve regulates revolutions per minute (RPM).

On the other hand has a seal or rubber gasket red, to completely seal the compartment and prevent leakage of vacuum or pressure in the intake manifold, therefore for proper operation of the engine idling is vital that this stamp it is in perfect condition.

The black connector contains four terminals, two corresponding to a coil and the other two to the second coil.

These coils are isolated from each other and must have the same electrical resistance, so you can often determine if the Chevrolet Silverado valve IAC is in good electrical condition.

To measure the electrical resistance of each coil use the MULTIMETER FUNCTION OHM (Greek letter Omega Ω), the value of each coil is in the range of 30Ω to 100Ω, this depends on the manufacturer of the IAC valve, BUT VALUE OBTAINED MUST BE THE SAME FOR BOTH COILS.

There may be a small difference of about 2 or 3 ohms (Ω), say that a coil has 48Ω, then the second coil may be 50Ω, which would indicate that he's fine.

If a coil sets a very low value, for example 10Ω or less then the IAC valve is defective, on the other hand, the coil can also set a high value, for example 1k or more, in this case also the IAC is damaged.

Location Chevrolet Silverado IAC valve

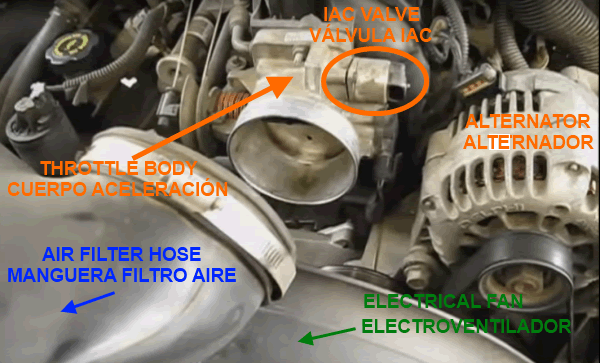

It is very easy to find the Chevrolet Silverado IAC valve, is located on the throttle body, secured with two Torx screws.

Follow the hose or duct filtered air, ie the hose connecting the air filter to the throttle body as shown in the following picture.

Chevrolet Silverado IAC valve is controlled from the computer of the truck (ECU / ECM / PCM) via a 4-pin connector, SEE PICTURE ABOVE.

Testing and maintenance of the Chevrolet Silverado IAC valve

If the engine has difficulty ignition, RPM are unstable: RPM may rise and suddenly down then up again or even go down while the engine is turned off, then there may be a problem dirt from the IAC, a power failure or mechanical failure.

Check that is securely fastened with Torx screws, rubber seal in place and in good condition, connector firmly located. If all this is right, then we must review the IAC valve free of soot and the air intake duct to the engine is.

We should always clean the soot from the IAC or any other substance that prevents free movement of the shaft and the top of the IAC. As I described above we use an ohmmeter to measure the resistance of coils, which should give equal values between 30 ohms and 100 ohms, 57 ohms say get both coils.

To lubricate the IAC valve can use a couple of drops of fine oil, such as 3 to 1, or sprayed with WD40, around the axis for internal lubrication.

Before installing the IAC, previously cleaned, lubricated and undamaged seal valve firmly connect the corresponding connector. Verify that the shaft length is 28 mm from the base of the IAC, this is done so that the computer Silverado properly adjust the engine RPMs.